By: Duc Hoang

Editor: Trang Tran

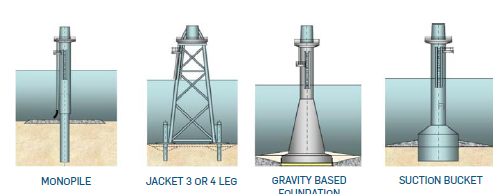

There are several types of foundation available for nearshore/ offshore wind towers. You may have heard of the names before: gravity-based structure (GBS), monopile, pile cap, jacket, tripod. The choice of foundation is one of the key determining factors in both technical and commercial feasibility studies of a nearshore/ offshore wind farm project.

-

- Water Depth and Met-ocean condition;

-

- Wind turbine class and frequency range;

-

- Geotechnical Survey;

-

- Constructability and installation technology of the Contractor;

-

- Material supply and local manufacturing portion,

-

- Construction timeline;

-

- Extreme natural conditions (storm, earthquake,).

Generally for a nearshore wind farm in very shallow water (depth between 3 m to 10m), we can immediately eliminate the jacket and tripod foundation types as they are simply suitable for greater water depth projects. Next, geotechnical survey is brought in to determine soil conditions below the seabed. Multiple borehole tests are drilled in to the seabed to determine how ’study’ the condition below is. For instance, the tests done on the Mekong Delta area Nearshore Wind project showed that the soil components below seabed consist of multiple layers of different conditions. Approximately 20m top layer is of very soft cohesive soil, turning to clay / sand with stiff, low SPT (Standard Penetration Test out).

Therefore, for such soil condition, the Gravity-based structure (GBS) is not the right type of foundation as GBS would be best used when we have firm and flat seabed. For a typical nearshore project in the Mekong Delta River, the feasible choices left for foundation are pile cap (pile group foundation) and monopile. Both options are ideal candidates to bear the full load of wind turbine either in idle or operational state on this specific seabed condition.

However, let’s see how construction feasibility and installation ability tests would help us further screen out another type of foundation which might be unsuitable for nearshore wind projects in Vietnam. Monopile’s piling work actually would be quite challenging for nearshore, shallow depth projects as it would require large jack-up vessels to drive those heavy piles into the seabed. Mobilizing these heavy vessels plus equipment to the piling location in certain shallow water locations is very difficult if not impossible.

Moreover, monopiles have to be premanufactured in offshore factories and thus, require long lead time for transportation to the project location. The pile cap option offers a better and more feasible solution for nearshore shallow water projects. The pile cap is a thick concrete mat-like structure which rests on a group of smaller piles, which gives a stable foundation. Smaller piles are easier to mobilize to the project location using barges. Barges are far better suited as shallow water transportation vessels. Pile group and pile cap, furthermore, can be manufactured locally and therefore, would require less time to transport to project sites via the Mekong Delta River network and/ or the East Sea.

A final consideration is the skillset and experience of local contractors. Whilst the local contractors have limited exposure and manufacturing experience of monopiles, there are numerous of contractors with track records in construction of pile cap structure.

As you can see, there are number of reasons why the pile cap structure is the usual foundation of choice for a nearshore project, especially those around the Mekong River Delta region. It is certainly not the only solution but generally is a better one in terms of feasibility. Binh Dai Wind Farm—monopile foundation Pile Different types of wind tower foundation cap foundation (Photos internet).